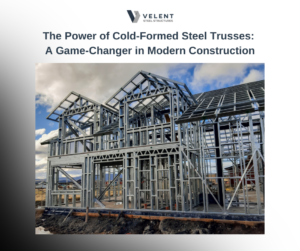

As construction techniques evolve, architects and builders are increasingly relying on Cold-Formed Steel (CFS) trusses to meet the demands of strength, efficiency, and design flexibility. Whether you’re working on a commercial complex, residential project, or an industrial facility, CFS trusses offer an innovative solution to overcome structural challenges while ensuring cost-effectiveness and sustainability.

In this blog, we’ll explore how CFS trusses are revolutionizing the construction industry and why they are the go-to choice for modern projects.

What Makes Cold-Formed Steel Trusses Unique?

Cold-formed steel trusses are crafted by bending thin sheets of galvanized steel into structural shapes without the use of heat. This process results in components that are:\n

- Lightweight but Strong: Offering a superior strength-to-weight ratio compared to traditional materials.

- Corrosion-Resistant: Ensuring durability even in harsh weather conditions.

- Precision-Engineered: Allowing for uniformity and customization to meet specific design requirements.

This unique combination of properties makes CFS trusses suitable for a wide range of construction applications.

Benefits of Cold-Formed Steel Trusses in Construction

a) Unparalleled Design Flexibility

CFS trusses are incredibly versatile, accommodating both simple and intricate roof and floor designs. Their ability to be custom-fabricated ensures compatibility with various architectural styles, from modern minimalism to traditional aesthetics.

b) Speed and Ease of Installation

Pre-engineered CFS trusses arrive at the construction site ready for assembly, reducing installation time significantly. This minimizes on-site labor costs and project delays caused by weather conditions.

c) Sustainability at Its Core

CFS trusses are 100% recyclable and produce minimal waste during manufacturing. Their long lifespan reduces the need for replacements, making them an eco-friendly choice for green building certifications.

d) Ideal for Long-Spanning Structures

With their ability to support heavy loads across large spans, CFS trusses eliminate the need for intermediate columns, creating open and spacious interiors. This is particularly beneficial for warehouses, auditoriums, and retail spaces.

e) Exceptional Resistance to Environmental Factors

CFS trusses are non-combustible, making them highly resistant to fire hazards. Additionally, they are immune to termites, mold, and corrosion when galvanized, ensuring durability even in the most challenging environments like coastal areas or humid climates.

f) Cost Efficiency Over Time

Although the initial cost of CFS trusses may be higher than traditional materials like wood, the long-term savings on maintenance, repairs, and replacements are significant. Their longevity and low lifecycle cost make them an economical choice for builders looking to optimize budgets.

Versatile Uses of Cold-Formed Steel Trusses Across Industries

Cold-Formed Steel (CFS) trusses have transformed how architects and builders approach various construction projects. Their adaptability, durability, and strength make them an ideal choice across multiple sectors:

a) Residential Construction

CFS trusses are becoming increasingly popular in residential projects for their ability to provide lightweight yet strong support. They are commonly used for:

- Roofs and floors, ensuring long-term structural stability.

- Modular housing, offering fast installation and precision for pre-engineered homes.

- Multi-family units, where fire resistance, soundproofing, and durability are essential.

b) Commercial Buildings

In commercial construction, CFS trusses excel at meeting the demands of large-scale projects, such as:

- High-rise office buildings, reducing the load on foundations and enabling flexible interior layouts.

- Shopping malls, where open and column-free spaces are critical.

- Hospitality projects, ensuring rapid construction timelines while maintaining aesthetic appeal.

c) Industrial Facilities

For industrial spaces, such as factories and warehouses, CFS trusses provide the strength and adaptability required to:

- Support heavy equipment and machinery.

- Span long distances without the need for intermediate supports, maximizing usable space.

- Ensure durability against harsh environmental conditions, such as moisture or chemicals.

d) Agricultural Buildings

CFS trusses are gaining traction in agricultural settings for constructing barns, greenhouses, and storage facilities. Their corrosion resistance and ability to withstand environmental stressors make them an excellent choice for:

- Structures in humid or corrosive environments.

- Buildings requiring rapid assembly to protect livestock or crops.

e) Renovation and Retrofitting

When upgrading or repurposing older structures, CFS trusses offer a lightweight and customizable solution to:

- Add new architectural elements without overloading existing foundations.

- Strengthen existing buildings for enhanced safety and compliance with updated building codes.

With their wide-ranging applications, CFS trusses continue to redefine possibilities in modern construction, adapting seamlessly to the unique requirements of each industry.

Real-Life Success Stories: CFS Trusses Making an Impact

Cold-Formed Steel (CFS) trusses have been game-changers in diverse construction scenarios, proving their adaptability, strength, and efficiency. Here are some noteworthy examples that highlight their practical applications:

Hurricane-Resistant Homes in Florida

In a sustainable housing project in Florida, developers prioritized resilience against extreme weather events, such as hurricanes and tropical storms. CFS trusses were chosen for their superior strength, lightweight nature, and corrosion resistance.

Impact: The homes constructed with CFS trusses demonstrated exceptional performance during hurricanes, withstanding high wind speeds and heavy rainfall.

Outcome: Construction timelines were reduced by 20%, and maintenance costs over time were significantly lower than traditional materials like wood.

Commercial Retail Development in Texas

A retail complex in Texas faced challenges related to large spans and open layouts for storefronts. CFS trusses were utilized to:

- Achieve expansive, column-free interiors ideal for retail space.

- Accelerate the project timeline through prefabrication and off-site assembly.

- Meet stringent fire safety codes required for commercial spaces.

Outcome: The project was completed 30% faster than initially planned, and the trusses provided the flexibility needed for tenant-specific customizations.

Modular Housing Development in Seattle

Seattle’s growing housing demand led to a modular housing initiative where speed, sustainability, and cost-effectiveness were critical. CFS trusses were chosen for the project due to their compatibility with prefabrication techniques.

- Key Advantages: Prefabricated CFS trusses allowed for quick assembly on-site, reducing construction waste and overall costs.

- Outcome: The project delivered affordable housing units faster than traditional methods, addressing a critical housing shortage in the region.

Emerging Trends in CFS Truss Technology

a) Integration with Advanced Digital Tools

Building Information Modeling (BIM) and other digital tools are revolutionizing how CFS trusses are designed and implemented. Architects and engineers can now use BIM to:

- Optimize structural designs for better performance.

- Reduce errors during manufacturing and assembly.

- Enhance collaboration among stakeholders for efficient project management.

b) Sustainability Through Green Steel Initiatives

As the construction industry embraces greener practices, CFS truss manufacturing is also evolving. Initiatives like using recycled steel and reducing carbon emissions in production are gaining traction, making CFS a more eco-friendly choice.

c) Hybrid Construction Systems

The integration of CFS trusses with other innovative materials, such as cross-laminated timber (CLT) or precast concrete, is paving the way for hybrid construction systems. This approach combines the strengths of multiple materials to:

- Achieve unique architectural designs.

- Improve thermal efficiency and acoustic performance.

d) Customization Through Advanced Manufacturing Techniques

Modern manufacturing methods, including 3D printing and laser cutting, are enhancing the customizability of CFS trusses. These techniques enable architects to:

- Create intricate, one-of-a-kind designs.

- Adapt trusses to unconventional shapes and layouts.

- Reduce lead times for highly specialized projects.

e) Increased Use in Emerging Markets

CFS trusses are rapidly gaining popularity in developing regions where cost-effective, durable, and disaster-resilient construction solutions are critical. As infrastructure demands rise, the adaptability and affordability of CFS trusses make them a go-to solution for:

- Affordable housing initiatives.

- Disaster recovery and reconstruction projects.

- Urban infrastructure development.

Conclusion: Build Smarter with CFS Trusses

Cold-Formed Steel trusses represent the future of construction. They bring unmatched strength, sustainability, and adaptability to every project, making them an ideal choice for architects and builders. Whether you are designing a residential masterpiece or a sprawling industrial facility, CFS trusses provide the reliability and innovation needed to bring your vision to life.

Explore tailored solutions for your next project by visiting our website. Let’s redefine construction, one CFS truss at a time.