In the evolving landscape of construction, choosing the right building material can significantly impact project efficiency, cost, and sustainability. Cold-formed steel (CFS) has emerged as a strong competitor to traditional building materials like wood, concrete, and hot-rolled steel. This comparative analysis explores the key differences, advantages, and potential limitations of cold-formed steel versus traditional materials, helping developers, architects, and contractors make informed decisions.

Traditional Building Materials Overview

Traditional building materials have long been the backbone of construction, providing strength, durability, and versatility. These materials include wood, concrete, and hot-rolled steel, each offering unique benefits suited for different types of projects.

- Wood

Wood has been a primary building material for centuries due to its availability, affordability, and ease of use. It is commonly used for framing in residential construction, as well as for flooring, roofing, and decorative elements.

- Advantages: Lightweight, renewable, and easy to cut or modify.

- Challenges: Prone to pests, rot, and fire, requiring regular maintenance and treatments.

- Concrete

Concrete is a composite material made from cement, water, and aggregates such as sand and gravel. Known for its compressive strength, concrete is widely used in foundations, walls, and large infrastructure projects.

- Advantages: Durable, fire-resistant, and capable of withstanding heavy loads.

- Challenges: Heavy, labor-intensive, and prone to cracking over time. The curing process can extend construction timelines.

- Hot-Rolled Steel

Hot-rolled steel is formed by heating steel to high temperatures and rolling it into various shapes. This material is favored for large commercial buildings, bridges, and high-rise structures due to its exceptional strength.

- Advantages: High load-bearing capacity and durability.

- Challenges: Heavier than CFS, which increases transportation and installation costs. Hot-rolled steel is also more expensive to produce and handle.

Comparative Insights

- Wood is best suited for small residential projects but lacks the durability required for larger structures.

- Concrete excels in foundational work and large-scale infrastructure but can slow down project timelines.

- Hot-Rolled Steel is ideal for skyscrapers and industrial projects but may not be cost-effective for smaller buildings.

Why Traditional Materials Are Still Used

Despite the rise of innovative materials like cold-formed steel, traditional materials remain popular due to their long-standing track record and familiarity within the industry. Each material plays a critical role, depending on the project’s scale, budget, and design requirements.

Understanding Cold-Formed Steel (CFS)

Cold-formed steel (CFS) is a versatile construction material made by bending and forming thin steel sheets at room temperature, without the need for heat. This cold-working process enhances the steel’s strength and durability, making it a reliable choice for structural framing, wall panels, and flooring systems in modern construction.

How It’s Made

Cold-formed steel begins as thin sheets or strips of steel that are passed through rollers to achieve the desired shape and thickness. These sheets are then formed into structural shapes such as C-channels, Z-sections, and box sections. The cold-forming process not only strengthens the steel but also allows for precision manufacturing with minimal waste.

Key Properties of CFS

- High Strength-to-Weight Ratio: Despite being lightweight, CFS can bear heavy loads, reducing the overall weight of structures.

- Corrosion Resistance: Galvanized or coated CFS is highly resistant to corrosion, ensuring long-term durability even in harsh environments.

- Non-Combustible: CFS does not ignite, contributing to enhanced fire safety in buildings.

- Dimensional Accuracy: CFS components are fabricated with high precision, ensuring consistency and reducing errors during assembly.

Applications in Construction

CFS is widely used in residential, commercial, and industrial projects. It is a key component in framing, load-bearing walls, roof trusses, and modular construction. Architects and engineers favor CFS for its adaptability and strength, allowing for complex designs and open floor plans without compromising structural integrity.

Why CFS is Gaining Popularity

- Speed of Construction: Prefabricated CFS components can be assembled quickly, reducing construction timelines.

- Sustainability: CFS is 100% recyclable and contributes to green building certifications.

- Cost Efficiency: The lightweight nature of CFS lowers transportation costs and reduces the need for heavy machinery on-site.

Comparative Analysis: CFS vs. Traditional Materials

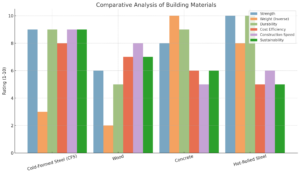

1. Strength and Durability

- Cold-Formed Steel:

CFS boasts a superior strength-to-weight ratio, allowing for lightweight structures without compromising load-bearing capacity. Its ability to withstand heavy loads while remaining light reduces stress on foundations, lowering overall material costs. - Wood:

While wood is strong, it is susceptible to warping, rot, and pest infestations, which can reduce long-term durability. Wood structures require ongoing maintenance and protection against environmental factors. - Concrete:

Concrete offers high compressive strength but lacks flexibility. Over time, cracks may develop, requiring repairs. It is also heavy, increasing transportation and handling costs. - Hot-Rolled Steel:

Hot-rolled steel provides excellent structural integrity but is significantly heavier than CFS, making it more challenging and expensive to transport and install.

Winner: Cold-Formed Steel – Its combination of lightweight properties and high strength gives it an edge in diverse construction applications.

2. Cost Efficiency

- Cold-Formed Steel:

The prefabrication and off-site panelization of CFS reduce on-site labor costs and construction time. Additionally, minimal material waste contributes to cost savings. - Wood:

Wood is generally less expensive upfront, but long-term maintenance and potential repairs can drive up costs. Fluctuations in wood prices can also impact budgeting. - Concrete:

Concrete is cost-effective for foundations but becomes expensive in complex structural designs. Curing time also adds to labor costs. - Hot-Rolled Steel:

The high cost of production and installation makes hot-rolled steel less economical for smaller projects.

Winner: Cold-Formed Steel – Reduced labor, faster timelines, and less waste make CFS more cost-effective over the project lifecycle.

3. Sustainability and Environmental Impact

- Cold-Formed Steel:

CFS is 100% recyclable, contributing to sustainable construction practices. The minimal waste generated during fabrication aligns with green building initiatives. - Wood:

Wood is renewable but contributes to deforestation. The carbon footprint of processing and transporting lumber can offset its sustainability. - Concrete:

Concrete production is energy-intensive and releases significant amounts of CO2, impacting the environment. However, its durability extends the lifespan of structures. - Hot-Rolled Steel:

Like CFS, hot-rolled steel is recyclable, but the energy required for its production is higher than that for cold-formed steel.

Winner: Cold-Formed Steel – Its recyclability and lower carbon footprint position it as the more sustainable option.

-

Construction Speed and Efficiency

- Cold-Formed Steel:

CFS allows for prefabrication, enabling faster on-site assembly. This accelerates project timelines and reduces delays. - Wood:

Wood structures can be assembled quickly but often require additional adjustments and reinforcements, which can slow down complex projects. - Concrete:

Concrete construction is labor-intensive and time-consuming due to the need for curing and formwork preparation. - Hot-Rolled Steel:

Although strong, hot-rolled steel requires more time for on-site welding and assembly.

Winner: Cold-Formed Steel – Prefabrication and lightweight properties lead to faster build times.

5. Design Flexibility

- Cold-Formed Steel:

CFS offers excellent design flexibility, allowing for creative, expansive layouts without compromising structural integrity. It supports open floor plans and can be easily adapted during construction. - Wood:

Wood is easy to modify but lacks the strength to support large, open spaces without additional reinforcements. - Concrete:

Concrete allows for flexible designs but is difficult to modify once set. Structural changes often require demolition. - Hot-Rolled Steel:

Hot-rolled steel enables large, complex designs but is limited by its weight and handling challenges.

Winner: Cold-Formed Steel – Its adaptability makes it ideal for both residential and commercial projects.

-

Fire and Weather Resistance

- Cold-Formed Steel:

CFS is non-combustible and resistant to moisture, pests, and mold. It performs well in diverse weather conditions without warping or deteriorating. - Wood:

Wood is highly flammable and susceptible to damage from moisture and pests. - Concrete:

Concrete is fire-resistant but can crack under extreme temperatures. - Hot-Rolled Steel:

Hot-rolled steel offers fire resistance but can lose strength at high temperatures.

Winner: Cold-Formed Steel – Its fire and weather-resistant properties enhance structural safety.

Conclusion

When comparing cold-formed steel with traditional materials like wood, concrete, and hot-rolled steel, CFS consistently stands out in terms of strength, cost efficiency, sustainability, and design flexibility. Its ability to streamline construction processes and lower long-term maintenance costs makes it an attractive choice for developers and contractors seeking modern solutions.

At Velent, we specialize in providing high-quality cold-formed steel solutions tailored to meet the unique demands of your project. Explore how CFS can transform your next build by visiting velent.com today.