In an era where climate change and urbanization are redefining how we design and build, resilience is no longer a luxury—it’s a necessity. One material that has steadily risen to meet this challenge is Cold-Formed Steel (CFS). This innovative framing solution is proving to be an indispensable ally for architects, engineers, and builders who prioritize safety, efficiency, and sustainability.

In this blog, we’ll explore how CFS stands out as the ultimate material for disaster-resistant construction while offering insights beyond the obvious.

The Science Behind Cold-Formed Steel

Cold-Formed Steel is manufactured by rolling or pressing thin steel sheets at room temperature to achieve the desired shapes and structural properties. Unlike traditional materials, CFS is engineered for precision and uniformity, ensuring consistent performance across applications. Its high strength-to-weight ratio allows for lighter yet sturdier structures, reducing the overall dead load on foundations.

Key advantages of CFS include:

- Predictable performance under stress, as it adheres to stringent manufacturing standards.

- Corrosion resistance, especially when coated with protective layers like zinc or aluminum-zinc alloys.

- Adaptability, enables designers to create intricate and customized structural layouts.

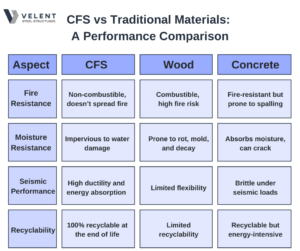

CFS vs. Traditional Materials: A Performance Comparison

While materials like wood and concrete have long been staples in construction, they fall short in several critical areas when compared to CFS. Here’s a closer look:

Real-World Applications: How CFS Excels in Disaster Zones

a) Hurricane-Prone Regions

Hurricanes and high winds demand materials that can withstand extreme lateral forces. CFS’s high strength-to-weight ratio and flexibility make it ideal for such conditions. Unlike wood, which can warp or break under pressure, CFS structures maintain their integrity, ensuring occupant safety.

Case Study: In Florida, a state frequently battered by hurricanes, CFS framing has become a go-to solution for builders aiming to meet strict wind-load requirements set by the Florida Building Code.

Beyond wind resistance, CFS’s ability to maintain structural connections under immense pressure minimizes damage and speeds up recovery efforts after a storm. This is particularly vital for essential infrastructure such as hospitals and emergency shelters, where operational continuity is critical.

b) Flood-Prone Areas

Flooding not only weakens structural materials but also creates a breeding ground for mold and bacteria. CFS’s resistance to water damage ensures that it remains unaffected even after prolonged exposure to moisture. This reduces repair costs and prevents health hazards for occupants.

Key Fact: Unlike wood, which swells and rots after flooding, CFS can be cleaned and reused, saving time and money.

CFS’s resistance to corrosion, especially when coated with galvanized or aluminum-zinc finishes, adds another layer of protection in flood-prone areas. Its ability to withstand prolonged exposure to humid and wet environments makes it ideal for coastal and riverine construction projects.

c) Seismic Zones

Earthquakes subject buildings to sudden and unpredictable forces. CFS’s ductility—its ability to bend without breaking—allows it to absorb and dissipate energy efficiently. This makes it a preferred material in seismic hotspots such as California and Japan.

In addition, CFS structures can be designed with modular connections, allowing damaged components to be replaced easily without compromising the entire structure. This adaptability reduces repair costs and ensures quicker rehabilitation after seismic events.

d) Fire-Prone Areas

In regions prone to wildfires, CFS offers a significant advantage due to its non-combustible nature. Unlike wood, which can ignite and fuel fires, CFS can withstand high temperatures without losing its structural integrity. This makes it an ideal material for building fire-resistant walls, roofs, and frameworks, safeguarding both lives and property.

Case Study: In Paradise, California, a town devastated by the 2018 Camp Fire, builders have turned to fire-resistant materials like Cold-Formed Steel to rebuild homes and commercial spaces. CFS has proven a reliable option, as it resists ignition and does not contribute to the spread of flames, providing an added layer of protection in high-risk wildfire zones.

The Future of Resilient Construction with CFS

As we face increasing challenges from climate change and urban population growth, the demand for disaster-resilient and sustainable construction materials will only grow. CFS is well-positioned to lead this transformation, offering unparalleled advantages in safety, efficiency, and environmental stewardship.

Emerging Trends to Watch:

- Greater Integration of CFS in Modular and Prefabricated Construction: The growing demand for efficient construction methods has positioned CFS as a cornerstone of modular and prefabricated building projects. With its lightweight properties and ease of transportation, CFS enables factories to produce components with exceptional precision, significantly reducing on-site construction time and labor. As urbanization continues, modular construction using CFS is expected to expand, particularly in densely populated cities seeking quicker and more sustainable housing solutions.

- Technological Advancements in CFS Manufacturing: Innovations in manufacturing processes are pushing the boundaries of what CFS can achieve. For instance, the adoption of advanced 3D roll-forming technologies allows for greater customization of steel profiles, meeting the specific needs of complex architectural designs. Additionally, research into hybrid CFS systems is enabling the combination of steel with other materials to enhance overall performance and efficiency. These advancements ensure that CFS remains a future-proof choice for modern construction.

- Increased Adoption of CFS in Emerging Markets: As emerging economies face the dual challenge of rapid urbanization and vulnerability to natural disasters, CFS is gaining traction as a viable solution. Countries in Southeast Asia, Africa, and Latin America are increasingly incorporating CFS into their building codes and construction practices. The material’s affordability, resilience, and ease of installation make it a particularly attractive option for these regions, where infrastructure development is critical to economic growth.

Conclusion: Why Choose CFS for Your Next Project?

Cold-Formed Steel is more than just a construction material; it’s a solution to some of the most pressing challenges in modern building design. Its ability to withstand natural disasters, reduce environmental impact, and deliver long-term cost savings makes it an indispensable choice for forward-thinking builders and developers.

Whether you’re constructing in a hurricane zone, or an earthquake-prone area, or simply looking for a material that combines sustainability with performance, CFS offers a future-proof solution. Let’s build safer, smarter, and more resilient structures—with Cold-Formed Steel leading the way.

Discover how our tailored solutions make your next project disaster-resilient and efficient. Connect with us to transform your construction goals into reality.