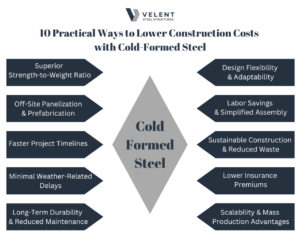

Today, with high competition in the construction sector, the importance of controlling project costs without affecting their quality cannot be emphasized more. Developers, builders, and architects continually discover materials and techniques that help reduce expenses while maximizing efficiency and sustainability. Cold-Formed Steel (CFS) framing has been recognized as the game-changing solution to drive savings along various cost lines of a project throughout its lifecycle.

From waste reduction to accelerating build times, CFS offers significant advantages beyond any initial material cost. Let’s look at ten practical ways cold-formed steel can contribute to reducing total construction costs.

-

Superior Strength-to-Weight Ratio

Cold-Formed Steel’s superior strength-to-weight ratio is one of its most significant advantages. Even though it is lightweight, it is incredibly strong, allowing for reduced foundation requirements. This lighter material reduces the load on structural elements, minimizing the need for heavy-duty foundations often necessary with materials like concrete or wood.

By requiring less material in the foundation and supporting structures, project costs decrease significantly. Additionally, lighter materials simplify transportation and reduce handling costs on-site, further enhancing overall savings.

-

Off-Site Panelization and Prefabrication

Cold-formed steel components can be prefabricated off-site, which facilitates accurate production and expedites the assembly process at the site. This panelization process leads to a reduction in errors and minimizes material waste, thereby decreasing the necessity for on-site modifications and rework.

Prefabrication speeds up construction and saves on labor. With components already prepared to be assembled on-site, projects can be advanced much faster, hence reducing any form of interference and still keeping up with schedules. This therefore results in short construction times that translate to less financing and overhead costs.

-

Faster Project Timelines

In construction, time directly correlates with cost. Delays increase labor expenses, extend rental equipment costs, and slow the return on investment. Cold-formed steel’s prefabricated components and easy installation significantly reduce build times compared to traditional materials.

With CFS, crews can complete framing quickly, allowing subsequent trades to begin their work earlier. This sequential benefit not only accelerates project timelines but also reduces the financial burden of prolonged construction phases.

-

Minimal Weather-Related Delays

Cold-formed steel does not warp, swell, or deteriorate due to moisture as wood does. Thus, it is best suited for projects where the weather conditions are not very predictable.

As CFS can be installed in nearly all weathers without affecting performance, projects are less prone to suffer costly delays because of environmental factors. Uninterrupted workflows and a lesser number of weather-related stoppages help keep budgets intact.

-

Long-Term Durability and Reduced Maintenance

Cold-formed steel is very durable, hence resistant to pests, mold, rot, and fire. Structures constructed using CFS require less maintenance over their lifespan, hence less frequent and costly repairs.

Through the reduction of risks associated with termites, moisture damage, and fire hazards, CFS reduces the need for constant interventions and replacements. These long-term savings make steel an inexpensive material for developers who aim to maximize the lifespan of their investments.

-

Design Flexibility and Adaptability

Steel’s flexibility allows architects and designers to create open floor plans and expansive layouts without compromising structural integrity. This adaptability enhances the aesthetic appeal of a building and contributes to cost savings.

The use of steel makes it easy to change designs while the building is under construction or even after it has been completed, thus allowing for easy additions or reconfigurations. This inherent flexibility reduces the need for costly structural reinforcements and ensures that the building can grow in response to changing needs.

-

Labor Savings and Simplified Assembly

The ease of assembling cold-formed steel frames reduces the reliance on highly specialized labor. Compared to materials like concrete, which require skilled masons or formwork carpenters, CFS components can be installed by smaller crews with standard training.

By streamlining labor requirements and simplifying assembly processes, CFS reduces overall labor costs. Additionally, fewer labor hours lead to a shorter project duration, contributing to overall savings.

-

Sustainable Construction and Reduced Waste

Sustainability has become a major concern in the construction industry, and cold-formed steel fits perfectly into initiatives on green building. Steel is 100% recyclable and can be reused multiple times without losing its structural properties. This reduces the environmental impact of construction projects while contributing to a circular economy.

Moreover, the precision of off-site fabrication ensures that material waste is minimized. Less on-site waste means lower disposal costs and fewer resources spent on excess materials, driving cost efficiency throughout the project lifecycle.

-

Lower Insurance Premiums

Buildings made of cold-formed steel, being fire-resistant, pest-proof, and mold-resistant, generally qualify for lower insurance rates. Insurance companies recognize the improved safety and durability of the steel-framed structure that lowers risk and claims.

Reduced insurance premiums are a direct cost-saving benefit to developers, making steel a more affordable and attractive construction material overall.

-

Scalability and Mass Production Advantages

For larger projects or developments that require repetitive designs, cold-formed steel offers significant scalability advantages. Mass-producing steel components ensure consistency and drive down costs through economies of scale.

This scalability makes CFS particularly suitable for large residential complexes, commercial developments, and modular construction. By leveraging mass production techniques, developers can achieve greater cost efficiency and uniform quality across projects.

Conclusion

Cold-formed steel is changing the face of the construction industry by offering innovative solutions to drive cost efficiency, enhance durability, and make project timelines more efficient. From the foundation to the final product, CFS delivers value at every stage of construction.

Cold-formed steel provides an opportunity for developers and builders to build smarter, faster, and more affordably when facing the challenges of rising material costs and labor shortages. By integrating CFS into future projects, the construction industry can meet the changing demands without sacrificing quality or profitability.

At Velent, we specialize in providing cost-effective cold-formed steel solutions to help you maximize efficiency and reduce construction costs without compromising quality. Visit velent.com to learn how our expertise can transform your next project.